VR is new technique of model drawing and designs. Manufacturing industry is in continual use of Computer Aided Designing Softwares in product design process. Virtual Reality has added a another dimension in product design and development.

Phases in product design and development and Challenges

Currently mostly models are made in 1:24 scale for the design review. The process in itself involves many challenges.One of the challenge is prototype product design services. Foremost difficult situation was to create the model with hands in accurate measurements and ratios. Now 3D printer have given aid in designing but they are unable to give the inside view of the model. Such models are unable to give the estimated use of space. In the 3D model created by printer it is impossible to check the ergonomic workspace.

Ideation to innovation needs ergonomical understanding to make the new product demanding. Innovation with design can be more effective if the user gets realtime effects of the changes. Its impossible to check ergonomic workspace in real time with physical prototyping or physical designing methods.

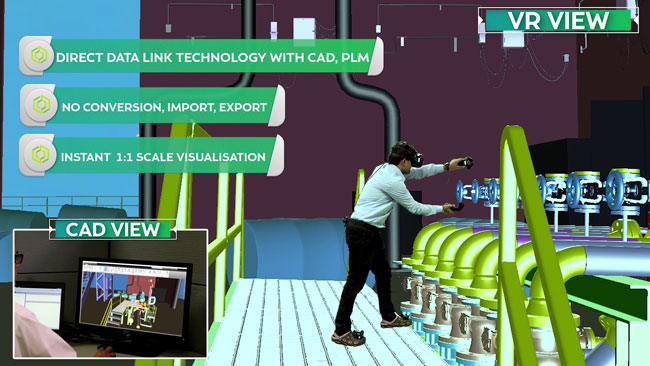

VR has enabled the user to convert their CAD Data into Virtual Objects that can be observed in multiple spectrum. CAD to VR Design softwares has emerged as a solution of all the constraints of physical world.

No Loss of data, Reduce human errors in model creation, relativity maintained if single change is made.

Currently some of the company has shown their innovative minds in the field of immersive visual experience with virtual reality experiences. They are developing tools which will reduce design implementation cost to minimise errors in product design and development. These firms are working on affordable VR solutions to help the industry grow.

2020 VR Applications for Heavy Engineering designs will be:

1. NX and 360° by Siemens

2. Catia by Dassault

3. Exxar by Vizexperts

4. Vuforia by PTC

5. Iris VR for Navisworks (Autodesk)